Electric arc furnace

Low operating rate of EAF steelmaking, high pressure on graphite electrode enterprises Recommend

Low operating rate of EAF steelmaking, high pressure on upstream graphite electrode enterprisesIn the past two years, China's electric arc furnace overall operating rate has been at a relatively low level, resulting in insufficient demand in the upstream graphite electrode market. In addition, manufacturers of graphite anode materials have purchased a large number of raw ma... ...

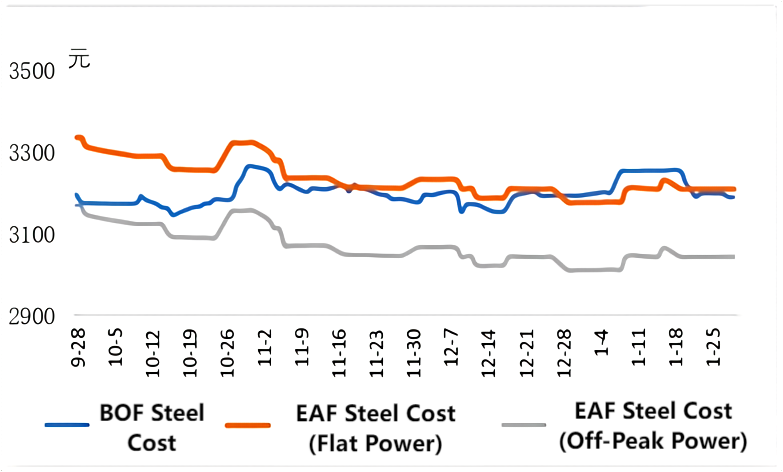

【EAF Steel】Steel Prices Stable as Long Holiday Approaches for EAF Mills

Graphite electrodes are the essential consumables in EAF steelmaking. Due to their outstanding electrical conductivity and excellent high-temperature resistance, they play a critical role in ensuring efficient and stable furnace operation, thereby improving steel production capacity and product quality.【EAF Steel】Steel Prices Stable as Long Holiday Approaches for EAF Mills This... ...

【Steel Industry】Annual Profits Up Threefold Year-on-Year

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking!【Steel Industry】Annual Profits Up Threefold Year-on-Year According to the latest dat... ...

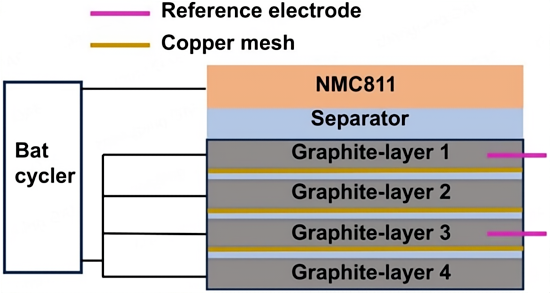

【Graphite Electrode】Internal Heterogeneous Reactions

【Graphite Electrode】Internal Heterogeneous Reactions Professor Li Wang's team and Professor Xiangming He's team from Tsinghua University published an article in Energy Materials (EM):Real-time monitoring of current density reveals the evolution of reaction heterogeneity inside graphite electrodesYan, Z.; Wang, L.; He, X. Unveiling the pattern and progression of reactio... ...

【Steel】Outlook for China's Steel Industry Under Declining Domestic Demand and...

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking! 【Steel】Outlook for China's Steel Industry Under Declining Domestic Demand and R... ...

【Graphite Electrode】Up 4.31%! Strong Cost Support in 2025, Slight Uptrend Expected in 2026

【Graphite Electrode】Up 4.31%! Strong Cost Support in 2025, Slight Uptrend Expected in 20262025 Market OverviewIn 2025, the graphite electrode market showed a "rise – fall – rise" price trend, basically moving in line with upstream low-sulfur petroleum coke prices. Overall, downstream demand remained weak throughout the year, and the actual market was strongly influenced by up... ...

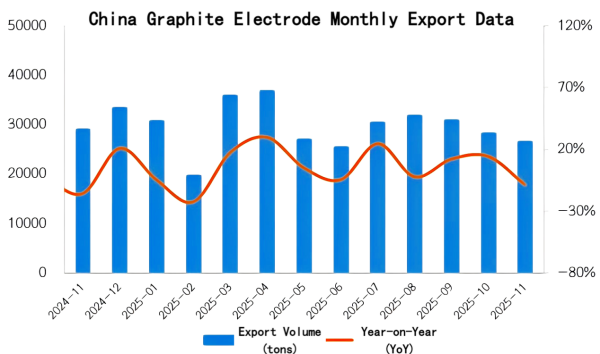

【Customs Data】 Down 6.41% MoM! China's Graphite Electrode and Needle Coke Import & Export Data ...

【Customs Data】 Down 6.41% MoM! China's Graphite Electrode and Needle Coke Import & Export Data for November 2025 Released 1. Graphite ElectrodesAccording to customs statistics, China's graphite electrode export volume in November 2025 was 26,300 tons, down 6.41% month-on-month and down 8.66% year-on-year.From January to November 2025, China's total graphite electro... ...

Low operating rate of EAF steelmaking, high pressure on graphite electrode enterprises Recommend

Low operating rate of EAF steelmaking, high pressure on upstream graphite electrode enterprisesIn the past two years, China's electric arc furnace overall operating rate has been at a relatively low level, resulting in insufficient demand in the upstream graphite electrode market. In addition, manufacturers of graphite anode materials have purchased a large number of raw ma... ...

Low operating rate of EAF steelmaking, high pressure on graphite electrode enterprises Recommend

Low operating rate of EAF steelmaking, high pressure on upstream graphite electrode enterprisesIn the past two years, China's electric arc furnace overall operating rate has been at a relatively low level, resulting in insufficient demand in the upstream graphite electrode market. In addition, manufacturers of graphite anode materials have purchased a large number of raw ma... ...

【EAF Steel】Steel Prices Stable as Long Holiday Approaches for EAF Mills

Graphite electrodes are the essential consumables in EAF steelmaking. Due to their outstanding electrical conductivity and excellent high-temperature resistance, they play a critical role in ensuring efficient and stable furnace operation, thereby improving steel production capacity and product quality.【EAF Steel】Steel Prices Stable as Long Holiday Approaches for EAF Mills This... ...

【Steel Industry】Annual Profits Up Threefold Year-on-Year

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking!【Steel Industry】Annual Profits Up Threefold Year-on-Year According to the latest dat... ...

【Graphite Electrode】Internal Heterogeneous Reactions

【Graphite Electrode】Internal Heterogeneous Reactions Professor Li Wang's team and Professor Xiangming He's team from Tsinghua University published an article in Energy Materials (EM):Real-time monitoring of current density reveals the evolution of reaction heterogeneity inside graphite electrodesYan, Z.; Wang, L.; He, X. Unveiling the pattern and progression of reactio... ...

【Steel】Outlook for China's Steel Industry Under Declining Domestic Demand and...

Graphite electrodes are the "lifeline" of EAF steelmaking! As the core material for arc conduction and heating, they feature high conductivity and heat resistance, directly affecting molten steel quality and output. Mastering graphite electrodes means mastering the initiative in EAF steelmaking! 【Steel】Outlook for China's Steel Industry Under Declining Domestic Demand and R... ...

【Graphite Electrode】Up 4.31%! Strong Cost Support in 2025, Slight Uptrend Expected in 2026

【Graphite Electrode】Up 4.31%! Strong Cost Support in 2025, Slight Uptrend Expected in 20262025 Market OverviewIn 2025, the graphite electrode market showed a "rise – fall – rise" price trend, basically moving in line with upstream low-sulfur petroleum coke prices. Overall, downstream demand remained weak throughout the year, and the actual market was strongly influenced by up... ...

【Customs Data】 Down 6.41% MoM! China's Graphite Electrode and Needle Coke Import & Export Data ...

【Customs Data】 Down 6.41% MoM! China's Graphite Electrode and Needle Coke Import & Export Data for November 2025 Released 1. Graphite ElectrodesAccording to customs statistics, China's graphite electrode export volume in November 2025 was 26,300 tons, down 6.41% month-on-month and down 8.66% year-on-year.From January to November 2025, China's total graphite electro... ...